EPOXY FLOORS

Epoxy-based flooring systems are divided into three groups:

Epoxy-based flooring systems are divided into three groups:

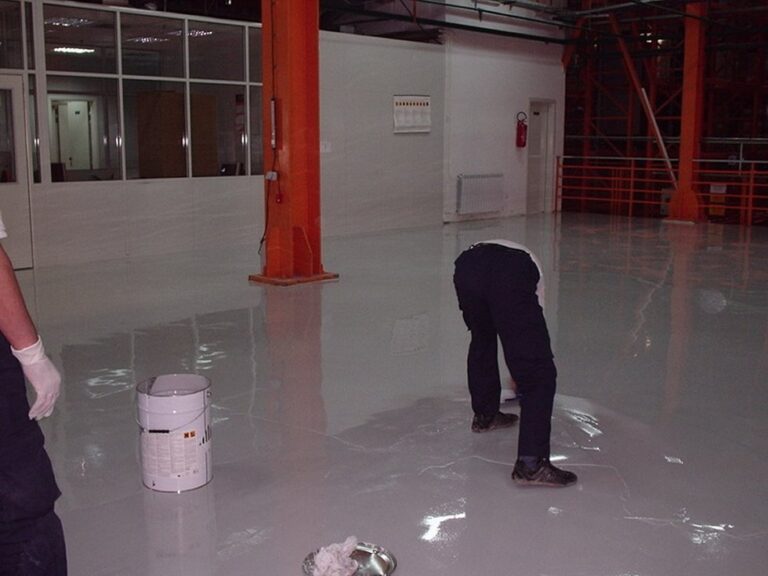

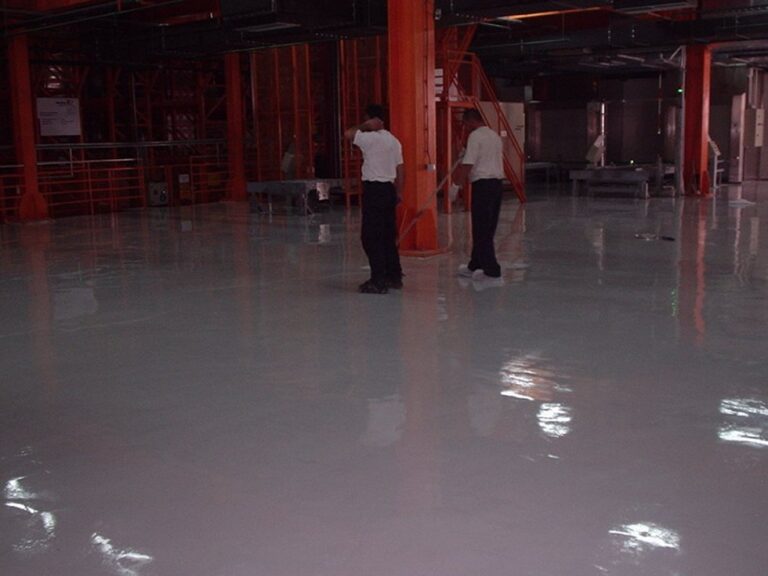

1. Two-component epoxy system – applicable as 0.05-0.08 mm thick coating, anti-dusting, mechanically loadable after seven days, chemically resistant, monolithic and jointless, watertight, non-slipping, non-skid/smooth, depending on the request can be in various colors, easy to maintain and repair

2. Two-component epoxy system – applicable as 03-05 mm thick selfcoating. This system also includes mounting battens at the floor and wall joint. Batten can be in different heights and radius, it enables easy floor cleaning and reduces maintenance costs. This flooring system is largely used in food and pharmaceutical industry, where HACCP, GMP and FDA standards are required. This is a multipurpose flooring system, wearproof, anti-dusting, mechanically loadable after seven days, chemically resistant, monolithic and joint free, watertight, non-slipping, and there is also possibility of applying a non-skid or smooth layer depending on the requests, it is available in various colors and easy to maintain and repair.

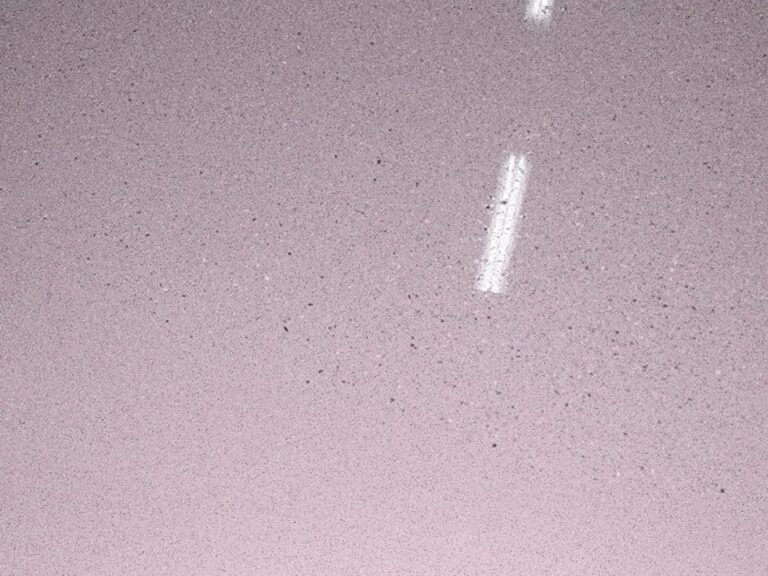

3. Three-component epoxy system – applied as a self-coating layer, designed for continuous static electricity discharge. Aside from the basic function – eliminating static charge, this group of anti-static floors features the following characteristics: multipurpose, wearproof, anti-dusting, mechanically loadable after seven days, chemically resistant, monolithic and joint free, watertight, non-slipping, and there is also possibility of applying a non-skid or smooth layer depending on the requests, it is available in various colors and easy to maintain and repair.

Application ares:military and defense industry, medical facilities, X-ray rooms, laboratories, surgery and anesthesia rooms, scanner rooms, rooms with electronic equipment, digital central bases, storages of easily flammable and explosive materials, transformer stations, printing houses, paint and lacquers production objects etc.

More than 35 years of QUALITY

[bauplus_reference]